The relationship between the surface treatment of elastic shock-absorbing buckle and the anti-rust a

2020-04-23

In general, the surface treatment of the buckle is directly proportional to the rust prevention ability, that is, the better the surface treatment, the stronger the rust prevention ability of the buckle, the worse the surface treatment, the worse the rust prevention ability of the buckle. So it can be said directly that the surface treatment of the buckle determines the corrosion resistance and service life of the product itself.

To understand the relationship between the two, we must first understand the surface treatment process of the buckle. The surface treatment of the buckle is divided into two types, spraying and electroplating. Spraying is also called baking paint, which is called out by the combination of chemical colors. The color is then subjected to high temperature to evenly attach to the surface of the buckle.

So what causes rust? One is uneven surface treatment, there are dead corners, and the other is scratches after surface treatment, which damages the surface layer. The plating layer on the surface of the buckle is the key to ensure the aesthetic and corrosion resistance of the buckle. In principle, the thicker the plating layer, the more adequate the plating, and the longer the plating time, the stronger the corrosion resistance of the surface.

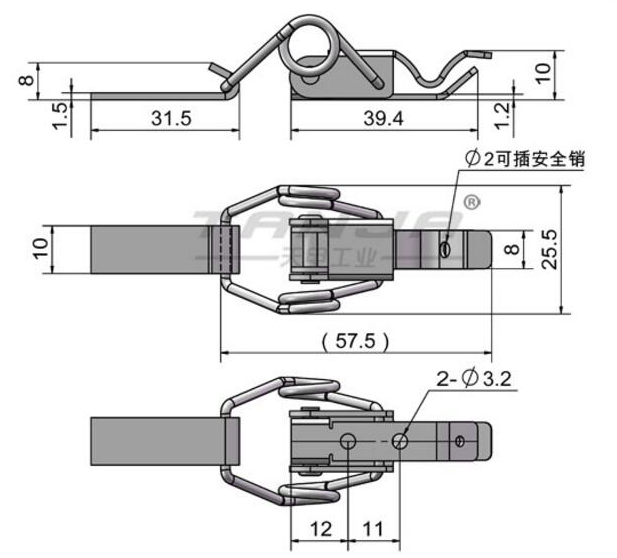

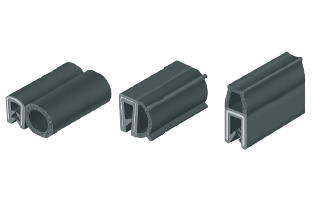

A59B-Elastic shock absorption buckle

Using SUS304 material

Wire ring spring damps vibration to maintain elastic preload

To understand the relationship between the two, we must first understand the surface treatment process of the buckle. The surface treatment of the buckle is divided into two types, spraying and electroplating. Spraying is also called baking paint, which is called out by the combination of chemical colors. The color is then subjected to high temperature to evenly attach to the surface of the buckle.

So what causes rust? One is uneven surface treatment, there are dead corners, and the other is scratches after surface treatment, which damages the surface layer. The plating layer on the surface of the buckle is the key to ensure the aesthetic and corrosion resistance of the buckle. In principle, the thicker the plating layer, the more adequate the plating, and the longer the plating time, the stronger the corrosion resistance of the surface.

A59B-Elastic shock absorption buckle

Using SUS304 material

Wire ring spring damps vibration to maintain elastic preload

Uses: food mold / toolbox / bridge

Tanjia one-stop purchasing platform Copyright © 2018 Adobe Systems Incorporated. All rights reserved.

Please select the language

Please select the language

m@tanja.com.cn

m@tanja.com.cn