Introduction to the surface treatment of elastic shock buckle

2020-04-23

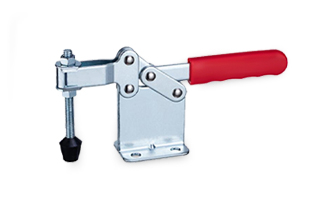

Surface treatment can be roughly divided into: electroplating, polishing, painting and so on. Paint spraying is a surface treatment method commonly used by hardware manufacturers at present, and the rusting of the buckle is prevented by paint spraying treatment. Electroplating is also a commonly used metal surface treatment processing technology. The surface of the product is plated through modern technology to ensure that the buckle will not rust even under long-term use.

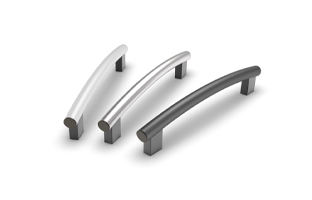

Surface polishing is commonly used in daily life. There are many buckles in the daily life. By deburring the surface of the buckle, some burrs on the edges and angles are polished to obtain a smooth surface, so that it will not be consumed Cause some unnecessary harm.

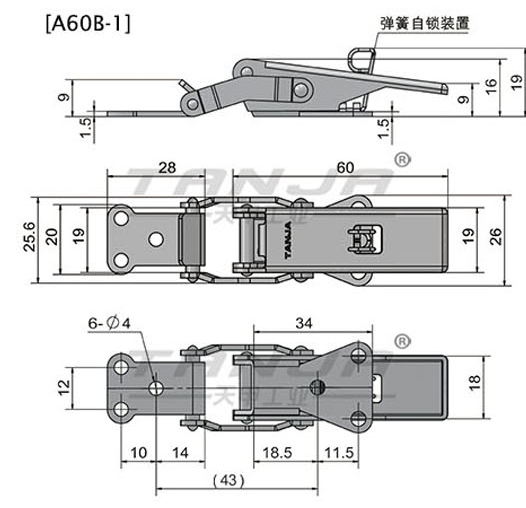

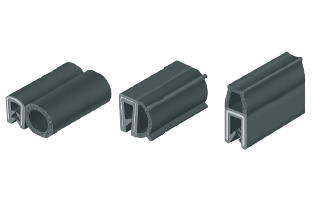

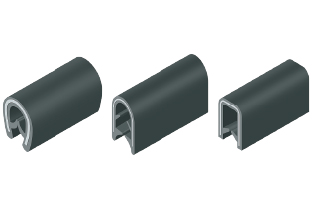

A60B-Elastic shock absorption buckle

Using SUS304 material

Self-locking device to prevent the buckle from accidentally bouncing

Surface polishing is commonly used in daily life. There are many buckles in the daily life. By deburring the surface of the buckle, some burrs on the edges and angles are polished to obtain a smooth surface, so that it will not be consumed Cause some unnecessary harm.

A60B-Elastic shock absorption buckle

Using SUS304 material

Self-locking device to prevent the buckle from accidentally bouncing

Uses: nuclear power equipment / high-end instruments / food / packaging and other machinery

Tanjia one-stop purchasing platform Copyright © 2018 Adobe Systems Incorporated. All rights reserved.

Please select the language

Please select the language

m@tanja.com.cn

m@tanja.com.cn